SeAH PR

SeAH NEWS 2022-08-17

SeAH Steel to supply Hyperloop tube to Hardt of Netherlands

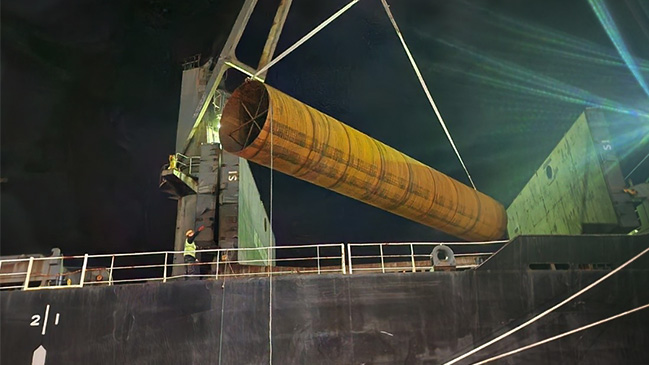

(Photo: The Hyperloop tube SeAH Steel is supplying to Hardt of Netherlands are being loaded.)

On the last 18th, SeAH Steel announced that it supplied the Hyperloop tube for to Hardt of Netherlands for the first time in Korea. Hyperloop is the next-generation eco-friendly mode of transportation where the magnetic levitation capsule travels inside the vacuum pipe at an ultra-fast speed.

The Hyperloop tube SeAH Steel manufactured in its Sooncheon Plant is a high value-added product with greater airtightness (which maintains the vacuum for a long period), vibration absorption and aseismic performances, as well as durability, than those of general steel pipes, thus ensures safety of Hyperloop train that travels at an ultra-high speed.

When manufactured the steel Hyperloop tube, SeAH Steel focused on maintaining accurate product dimensions considering the purpose of the product, and the company’s pipe manufacturing skills were well recognized as it satisfied Hardt’s strict requirement of 4mm or less tolerance in terms of external diameter.

Hardt of Netherlands who purchased the the tube from SeAH Steel is a global technology company that developed the Hyperloop track switching technology and successfully demonstrated its technology can enable the Hyperloop capsules can switch routes for the first time in the world. The Hyperloop tube manufactured by SeAH Steel is to be applied to the testing route of European Hyperloop Center, which is to be built by Hardt in Veendam, Groningen in Netherlands.

SeAH Steel raised the quality of its Hyperloop tube by using PosLoop 355, a material dedicated to Hyperloop tube jointly developed by POSCO and TATA Steel Netherlands. SeAH Steel is planning to expand its presence in the global Hyperloop markets on its track record of having supplied the pipe for Hyperloop to Hardt and by continuing to work with POSCO.

Man-gi Hong, Head of Sales Division at SeAH Steel, commented that “SeAH Steel’s development and commercialization of the Hyperloop tube is an evidence of the company’s commitment to ESG management. The tube can help the global community reduce carbon emission. SeAH Steel’s tube&pipe manufacturing capability and POSCO’s excellent products combined, SeAH’s pipe can bring success to the Hypertube R&D testbed creation project recently promoted by the Korean government. SeAH Steel will continue to support the efforts on commercializing Hyperloop around the world, leveraging the geographical advantage of its Sooncheon Plant being located near the Yeulchon Port which makes it easy for the company to ship a large structural product such as the Hyperloop tube."

List